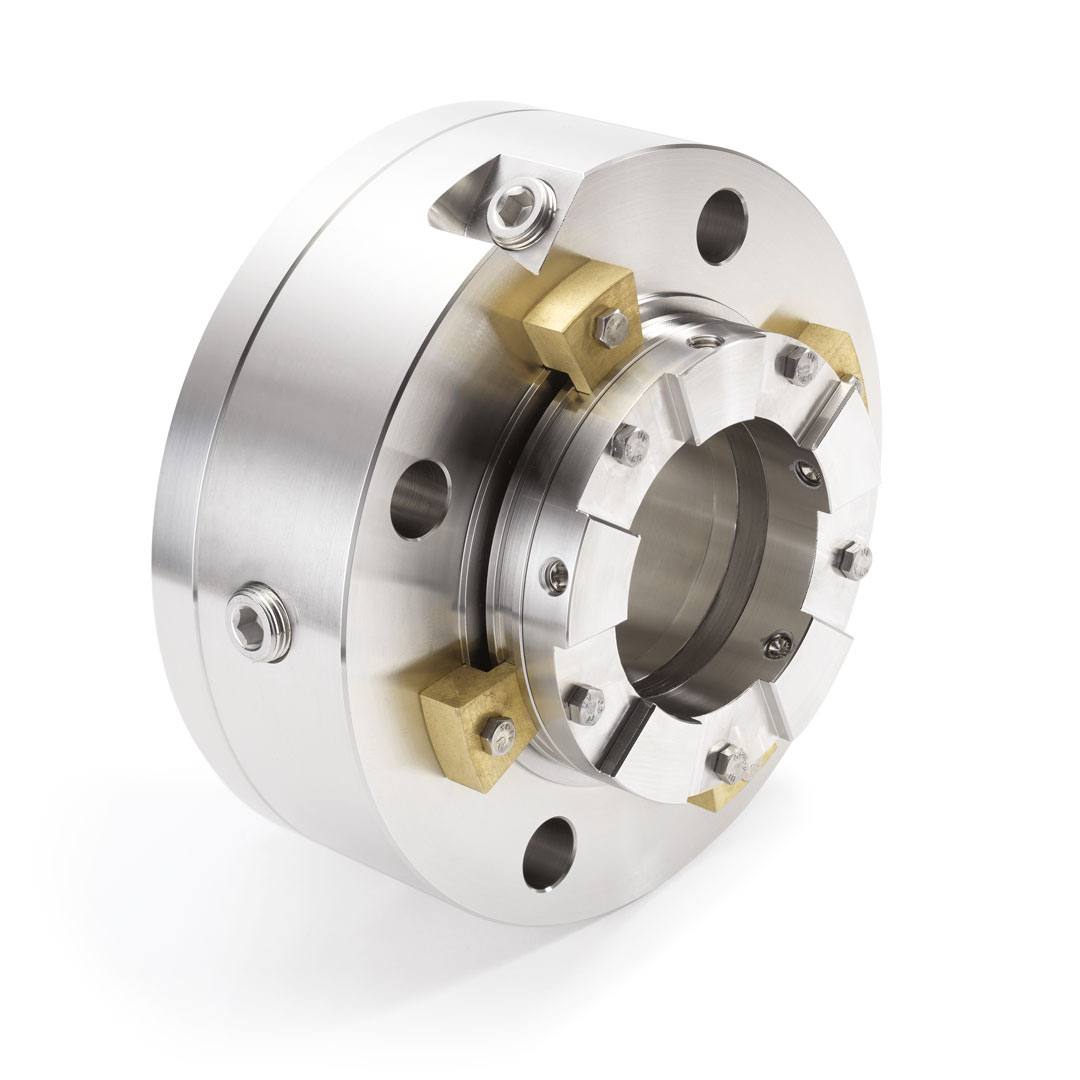

Dual Mechanical Seal – Oil & Gas

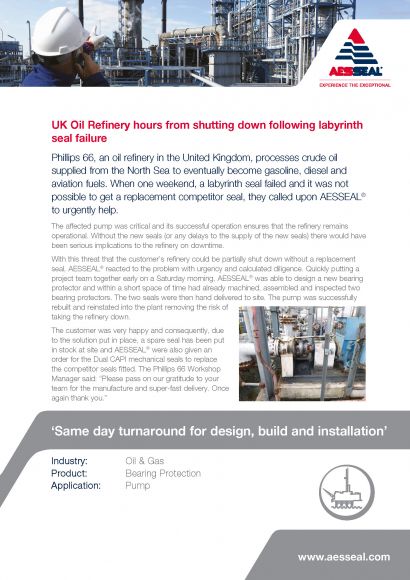

The AESSEAL® API Type A, B and C dual-seal range offers the user an unprecedented range of API engineered sealing solutions to suit all application requirements. The category 1, 2 and 3 seals are qualification tested to API 682. Modular design allows the users to select the right solution for their application, with the modular design ensuring simplicity of purchase and fast delivery.

CAPI™ Type A, B and C Category I Dual Seals

-

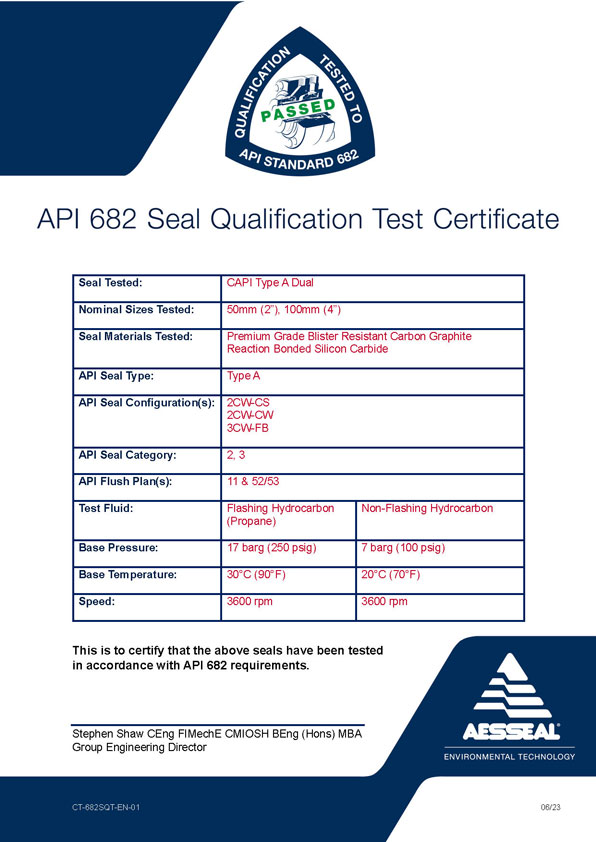

Employs Qualification Tested API 682 Technology

-

Thin cross-section (TXS) seal designs for mature asset installation including API 610, 5th Ed. with a 0.500" (12mm) radial cross-sectional space between the shaft and seal chamber

-

Robust and reliable seal face drive (Patented floating drive technology) reduces high stress points at equipment start-up

-

Probably the most compact dual API cartridge seals on the market which employ API 682 technology

-

All sizes available from 1.000" to 5.000" (24mm - 125mm)

CAPI™ Type A Category II and III Dual Seals

-

Qualification Tested to API 682

-

Stationary flexible element offered as standard for improved pusher design performance as outlined in API 682 Section 6.1.1.5.

-

Rotary design is available on request

-

Multi-port Flush design offered as standard for optimum seal face cooling

-

World-leading bi-directional pumping ring performance with 0.062” (1.5mm) radial clearance between rotor and stator; conforming with API 682 Section 8.6.2.3 without compromise

-

All sizes available from 0.750” to 4.375” (20mm - 110mm)

CAPI Type B Category II and III Dual Seals

-

Qualification Tested to API 682

-

Effective seal-face heat dissipation achieved by a directed barrier fluid flow path, irrespective of shaft rotational direction

-

Multi-port Flush design offered as standard for optimum seal face cooling

-

12 edge-welded bellows convolutions as standard

-

All sizes available from 0.750” to 4.375” (20mm - 110mm)

CAPI™ Type C Dual Seals

-

Qualification Tested to API 682

-

World-leading bi-directional pumping ring performance with 0.062” (1.5mm) clearance between rotor and stator, conforming with API 682 Section 8.6.2.3 without compromise

-

Effective seal-face heat dissipation achieved by directed barrier fluid flow path

-

Identical seal-face technology employed at the inboard and outboard positions

-

All sizes available from 0.750” to 4.375” (20mm - 110mm)

CAPI™ Containment Seals

-

Containment seal technology that exceeds the requirements of API 682 Ed 3, Section 4.2 and ISO 21049

-

High heat dissipation properties due to the AESSEAL® close coupled technology supplied in a robust, short working length pusher design

-

Eliminates the need for liquid barrier systems

-

Isolation bushing available

-

Modular design to all Type A, B and C configurations

-

Contacting and non-contacting design

-

Bi-directional option available

-

All sizes available from 0.750” to 3.625” (20mm - 90mm) larger sizes available on application